Spiral shields

Structural options

- Made from steel or spring steel

- Upon request, we can also supply flanges suitable for the spirals

- If you prefer to use other flanges, please check their suitability with our technical support team before use

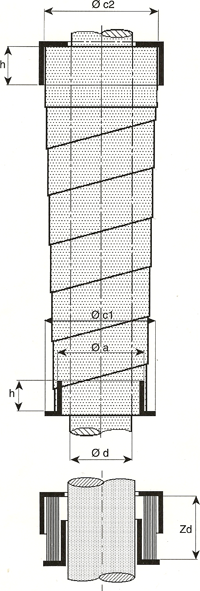

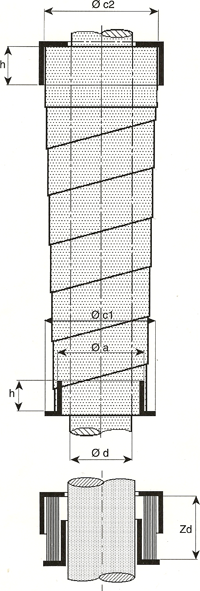

Dimensioning of flanges

The height (h) of the centred flange can be the same as the compressed dimension (Zd) of the spiral minus 2mm. However, it must be at least 2/3 of the compressed dimension.

WMB standard spiral shields

- Prevent premature shaft and spindle wear

- Maintain the efficiency of your machines and extend service intervals

- Improve occupational safety

- Enhance the appearance of the machines

- Self-cleaning and maintenance-free under normal operating conditions

- Can be installed vertically or horizontally

Made from high quality spring steel - Colour: steel blue

- Stainless steel available by special order

Installation directions for WMB spirals

Vertical installation

Standard installation of the WMB spiral: Always larger end up

Installation with the smaller end up is possible, but only after a separate consultation

Horizontal installation

The maximum elongation is reduced to 2/3 of that of vertical installation. This ensures optimal hardware performance

The larger end can be mounted left or right as required.

Depending on the model, the deflection of the WMB spiral is 1–3% of the maximum elongation.

Two WMB coils can be installed end to end, if necessary. In such cases, please contact our technical support team.

For more information, please call us, contact us using the contact form at the bottom of this page, or email us at maxjas@maxjas.fi

Trusted by

Miksi valita meidät kumppaniksi

Mauris neque nisi, faucibus non elementum in, convallis et eros. Sed pretium sem libero, vel pellentesque purus ultrices ut. In quis leo id massa pulvinar euismod cursus non justo.

Sed sagittis et urna non efficitur. Nulla nec lacus tincidunt, rutrum arcu in, euismod diam neque tellus, congue sed velit sed scelerisque.

Maecenas interdum lorem eleifend orci aliquam mollis aliquam non rhoncus magna suspendisse aliquet tincidunt enim.

- Maecenas interdum lorem

- Praesent mi sem tincidunt eget facilisis

- Sed pretium sem libero vel pellentesque

- Donec neque tellus congue sed velit

- Praesent mi sem tincidunt eget facilisis