Bellows covers

We supply a wide range of bellows covers. Our bellows are divided into four categories:

- Rectangular bellows

- Polygonal bellows

- Homogeneous bellows

- Telescopic bellows

More information regarding different bellows models and the solutions best suited to your needs is available in the type-specific sections on this page.

Rectangular bellows

Benefits

- Improved occupational safety

- Moving parts are protected

- Improves the appearance of both the machine and the working environment

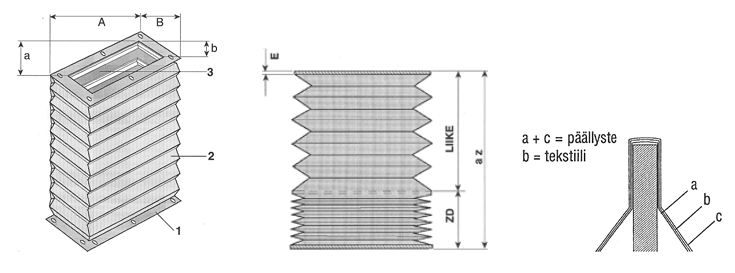

Structure

Each pleat can be equipped with a PVC frame, which guarantees the stability of the shape and the dimensions. The protective cover and the PVC frame are either welded or sewn together. A welded seam is permanently tight and provides oil-resistant protection, while a sewn seam is suitable for heavy mechanical duress. The conductor and the outer frames are manufactured to the customer’s dimensions and requirements.

Type | Materials |

|---|---|

002 | Woven polyester fabric coated with polyurethane on both sides Thickness 0.20 or 0.40 mm Trickle-resistant Oil- and emulsion-resistant |

0016 | Specially woven fabric gummed on both sides Flame-proof Excellent resistance to oil, fuel and chemicals Specially designed for use with lasers |

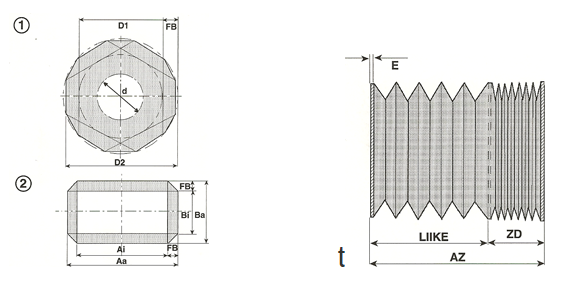

Polygonal bellows

Benefits

- Good shape stability even with large dimensions

- Available in a variety of materials

- Divided version available on request

- Fully sealed (with the exception of long extensions and high speeds, in which case use of additional valve openings is recommended)

Structure

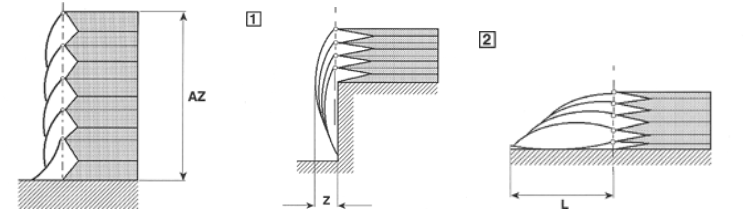

Polygonal bellows are available in hexagonal (Figure 1), octagonal (Figure 2), dodecagonal etc. versions. Alternately facing pleats provide excellent stability in large dimensions. These bellows guards are multi-layer laminated, which means that the woven textile fabric is glued to the inner material, thus guaranteeing stability and strength in large dimensions. These layers are further attached to a special outer material.

Type | Materials |

|---|---|

Polytex | Polyurethane coated polyester fibre

|

Putex | Silicone elastomer coated polyamide fibre

|

8 | Cotton fibre, plastic coating

|

10 | Cotton fibre, graphite coating

|

11 | Cotton fibre, aluminium coating

|

11 A | Fibreglass fabric coated with aluminium on one side

|

Other materials on request

|

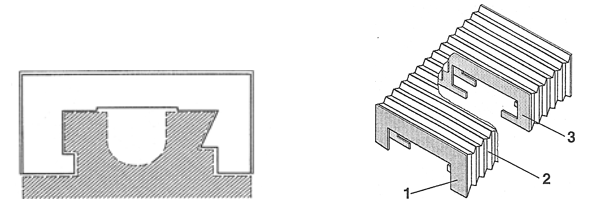

Homogeneous bellows

Benefits

- Single layer material

- Easy to move

- Retains shape

- State-of-the-art design

- High drive speeds

- Protective covers for guideways

Structure

Each pleat is equipped with a shape-retaining PVC frame. The protective cover and the PVC frame are either sewn or welded together. Welded seams are tight and oil-resistant, while sewn seams withstand heavy mechanical duress.

- 1 – Outer frame

- 2 – Protective cover

- 3 – PVC frame

Additional Information

The shape of the cover is designed to meet the customer’s specific needs. Our technical support team will identify the best possible form to meet your requirements. Upon request, we can also install additional rollers and sound-absorbing strips.

Type | Materials |

|---|---|

002 | Woven polyester fabric coated with polyurethane on both sides Thickness 0.20 or 0.40 mm Trickle-resistant Oil- and emulsion-resistant |

0016 | Specially woven fabric gummed on both sides Flame-proof Excellent resistance to oil, fuel and chemicals Specially designed for use with lasers |

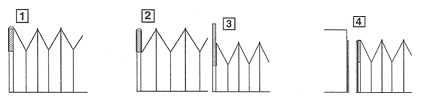

Mounting methods

The mounting method and the shape of the outer steel or PVC frame are selected in conjunction with the initial order, based on the customer’s drawing (Figures 1–3) or with the help of an adhesive tape tested by us (Figure 4).

The benefits of self-adhesive mounting

- Quick to install on the machine

- Secure attachment from -30 °C to +90 °C

- Tensile strength 2.94 N / cm²

- Firm grip even after 10,000 uses

- When using large amounts of oil or emulsion, the adhesive tape can be sewn to the frame, which is then screwed onto the machine.

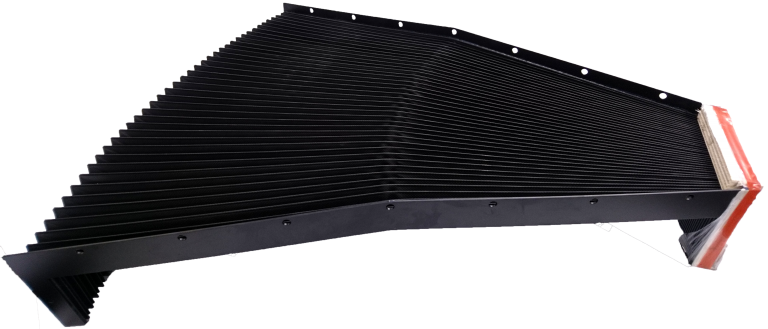

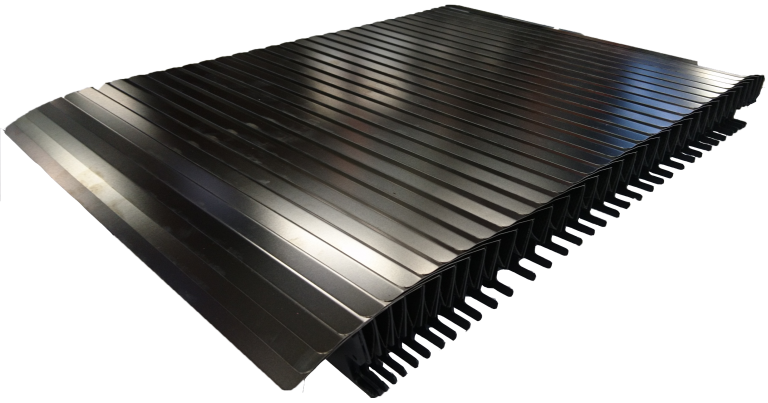

Flexible telescopic bellows

Benefits

- Articulated or interconnected support for telescopic plates

- Guaranteed protection for even a large amount of chips

- No glued joints

- Additional protection for emulsion available upon request

- Enable high drive speeds

- Stainless and acid-resistant telescopic plates

- Telescopic plates are easy to replace

Structure

The sturdily articulated shaft runs parallel to the ridges of the pleats. The telescopic plates are connected to the articulation without gluing, either with or without additional compression. The number of telescopic plates depends on the recommended extension of the cover. The method of attaching the outer telescopic plate depends on the application and environment of the bellows cover.

Trusted by

Miksi valita meidät kumppaniksi

Mauris neque nisi, faucibus non elementum in, convallis et eros. Sed pretium sem libero, vel pellentesque purus ultrices ut. In quis leo id massa pulvinar euismod cursus non justo.

Sed sagittis et urna non efficitur. Nulla nec lacus tincidunt, rutrum arcu in, euismod diam neque tellus, congue sed velit sed scelerisque.

Maecenas interdum lorem eleifend orci aliquam mollis aliquam non rhoncus magna suspendisse aliquet tincidunt enim.

- Maecenas interdum lorem

- Praesent mi sem tincidunt eget facilisis

- Sed pretium sem libero vel pellentesque

- Donec neque tellus congue sed velit

- Praesent mi sem tincidunt eget facilisis