Life cycle services for machine tool protection

Maxjas Oy has been in the business of industrial maintenance for nearly 30 years, and our main activity is to maintain, install and import CNC machine tool parts and part systems. Our company’s central product groups are way and bellows covers, chip conveyors and way lubrication systems.

We know from experience that when it comes to equipment and how it wears, it is not a question of if the machines will break down, but when. When we accept the fact that machines do not last forever, we can turn our attention to anticipating break-downs and preparing for them.

In our work, we have noticed that by providing life cycle services that are customised to our clients’ needs, we can provide machine shops with the best value for money invested in maintenance – from the moment when the machine tool cover is purchased, throughout its maintenance over its lifetime and all the way through to disposal. By predicting covers’ maintenance needs, we have successfully created continuous savings and avoided unnecessary production downtime.

Refurbishing a machine tool is often an expensive and time-consuming project that results in losses both through the immediate costs of maintenance as well as in terms of the time that the machine spends at a standstill. Machine tool refurbishment should therefore be prevented for as long as possible, and maintenance of way covers plays a major role in this.

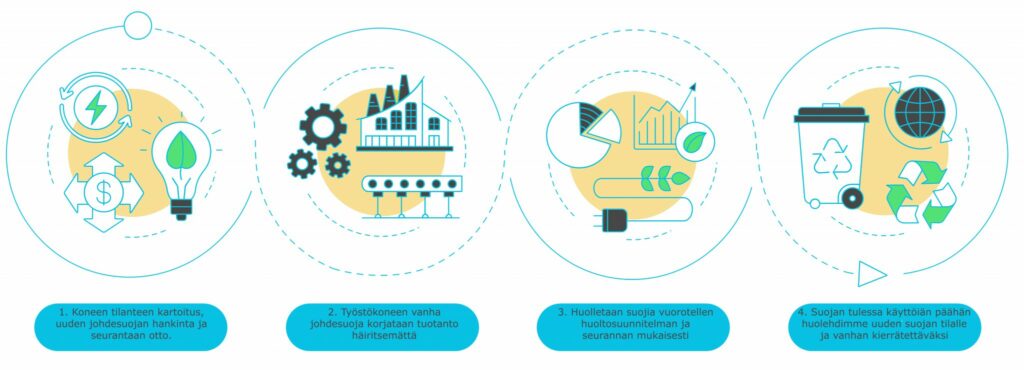

Life cycle operation model

1. Evaluating the machine’s condition, procuring a new way cover and monitoring it.

2. The machine tool’s old way cover is repaired without disturbing production.

3. Service the covers in turn according to the maintenance plan and observations.

4. When the cover reaches the end of its useful life, we deliver a new cover to replace it and recycle the old one

Life cycle services and predictability

Life cycle services help companies get a better understanding of maintenance as a whole and allow them to anticipate the next phase of maintenance ahead of time, be it annual maintenance, increased risk of downtime, or disposal and replacement of an old part.

By measuring the lifespan of components and parts, we can avoid unnecessary procurements made “just in case” and predict the likelihood of risks more accurately. Therefore, Maxjas Oy can focus on maintenance work where needed and improve its predictability by utilising the machine’s usage and history data. With the help of the existing data, we can more effectively predict what work needs to be carried out on machine tools and prepare for it well in advance of planned maintenance.

Trusted by

Miksi valita meidät kumppaniksi

Mauris neque nisi, faucibus non elementum in, convallis et eros. Sed pretium sem libero, vel pellentesque purus ultrices ut. In quis leo id massa pulvinar euismod cursus non justo.

Sed sagittis et urna non efficitur. Nulla nec lacus tincidunt, rutrum arcu in, euismod diam neque tellus, congue sed velit sed scelerisque.

Maecenas interdum lorem eleifend orci aliquam mollis aliquam non rhoncus magna suspendisse aliquet tincidunt enim.

- Maecenas interdum lorem

- Praesent mi sem tincidunt eget facilisis

- Sed pretium sem libero vel pellentesque

- Donec neque tellus congue sed velit

- Praesent mi sem tincidunt eget facilisis